In addition to complete air compressor overhauls, we also offer a wide variety of centrifugal compressor repair services. There isn’t a part that we can’t fix, fabricate, replace or rebuild. Our team has been working in the compressor industry for decades and is incredibly experienced in the operation of practically every compressor on the market.

We have years worth of experience with Ingersoll Rand repair, Joy/Cooper/Cameron repair, Dresser Rand repair, and even Atlas Copco repair. With quick turnaround times and the ability to do repairs both in house or at your facility, we’ll get your operation back up and running in no time.

Contact our emergency line with 24/7 availability to get the repairs on your compressor in the works and you back in business.

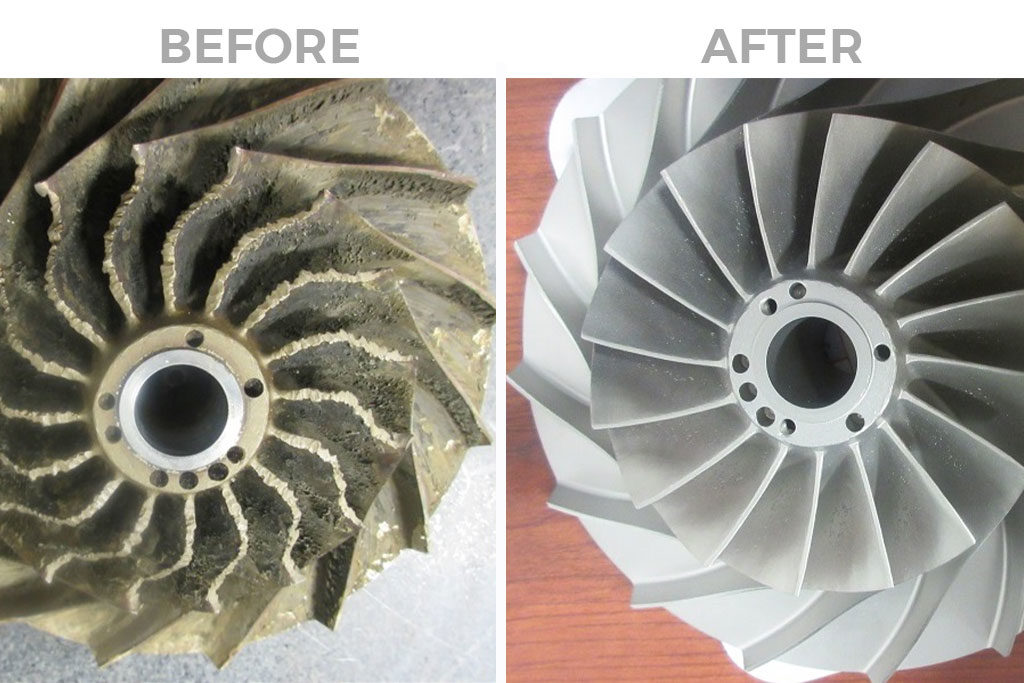

We’ll get your worn components repaired or replaced to like-new condition that will meet, or even exceed, the OEM specifications. Before you decide to replace your system, give us a call. We might have a repair option that will get you back up and running in a fraction of the time.

When downtime is an issue, an A.C.E. replacement air-end exchange is often the answer. Many times, either remanufactured or new internal components can be provided – just let us know. As with our overhauls, our air end exchanges are assembled by A.C.E. skilled technicians and verified correct through a documented process to ensure the highest quality every time.

To learn more about our process, the models we’ve serviced, or repair options for your compressor, call us today and one of our experienced team members will be happy to help you out.

Ingersoll Rand Centac

First generation CENTAC:

OC, 1C, 2C, 3C, 4C

Second generation CENTAC:

1CII, 2CII, 3CII, 5CII

Flange mounted motors:

OCV, 1CV, 2CV

Later Modified units:

1ACII, 2ACII, 1ACV, 1BCV

C950 (2ACII with a 3rd stage cooler and barrel added)

2CIIM3 (High Pressure 2ACII for soot blowing)

2ASB (High Pressure 2ACII for soot blowing)

Cooper / Cameron / Joy Centrifugal

C8 Line, TA18, TA28, TA38, TA48

MSG-2: TA26, TA30, TA35

MSG-3: TA40, TA50

MSG-4: TA60, TA70

MSG-6: TA100

MSG-8: TA150

MSG-12:

MSG-18:

TAV: TA17V, TA20V

TA2000, TA3000, TA6000

Dresser / Clark ISOPAC Centrifugal

All centrifugal frame sizes. First number of the Serial Number is the frame size (2-4-6), second is the number of stages (2-3-4) so a 6-4 would be a frame size 6 four stage unit.

Atlas Copco Centrifugal

ZH4000 / ZH7000, ZH6000 / ZH10000, ZH9000 / ZH15000

HA Single Stage, HR Two Stage, HL Three Stage, HM Four Stage

SC, GT

Services We Provide

- ANYTHING that touches or has anything to do with the units listed above.

- Complete centrifugal overhauls.

- Complete centrifugal remanufacters.

- New Centrifugal Units.

- A team of highly trained service technicians who are factory trained on CENTAC, Atlas and Joy units.

- An engineering department with new and reverse engineering capabilities.

- RAD reports.

- Lubricants, oil, air & oil filters, demisters and elements.

- Valve repair and new replacement.

- Blast wash and paint work.

- Air End exchanges.

- Aero-rerates.

- Vibration analysis.

- Air audits.

- Repair work of any kind. You name it. Gearbox, cooler bore, cooler barrels, piping, etc.

- Metal stitching, event pressure vessels.

- Moisture separator repair and refurbishing.

- Motor work: everything from PM to full overhaul with warranty.

- Laser alignment.

- Bore alignment inspection.

- Rotor repair, sleeving, chroming, grinding, welding etc.

- Dynamic balancing

- Field balancing

- Nondestructive testing: x-ray, mag particle, dye penatrent, impeller overspeed testing.

- Degaussing, both small parts like a pinion and large items like a gear box.

- Sleeved barrels IN STOCK!

- In-house cooler CTR.

- LARGE Inventory of new coolers in stock.

- New, remanufactured and used parts IN STOCK.

- AMP Program (Preventative Maintenance).

- Odd-ball or really old part sourcing. We will find it, or we will build it.